MJ Biotech

Company profile

Diabetology is the second largest therapeutic segment in the world. The market for pharmaceuticals for the combat and management of diabetes & its comorbidities is growing every day. Having been in the diabetes management industry for about 15 years with MJ Biopharm, we have developed the potential to take biotechnological research from concept to commercialization. We put our belief into action & in 2015, MJ Biotech was founded.

World over the biopharmaceutical sector is fast growing to provide safe, sustainable and affordable healthcare solutions. This sector is at a nascent stage in India and MJ Biotech is one of the pioneering companies in this field in our country.

Our core product is Human rDNA insulin API (Active Pharmaceutical ingredient) which has numerous applications in the diabetological drug industry. We have created a unique microbial platform to provide flexibility to the research and development of medical formulations. We leverage this platform in development of various other analogue insulin formulations that will reduce cost by production of bio-similar products.

Company Mission

We see tremendous potential for growth in this industry. We are in process of building a pipeline of products that have global sales potential of > $25 Billion. We want to offer unique mid-term and long-term sustainable biopharmaceutical opportunities & be a one-stop-solution for biotechnological solutions for various ailments.

Products

We are constantly developing our biotechnological process and innovating towards creating new products, that establish our brand firmly in the biopharmaceutical market. We have various formulations in the pipeline that will change diabetes management for the better.

Manufacturing & Quality Assurance

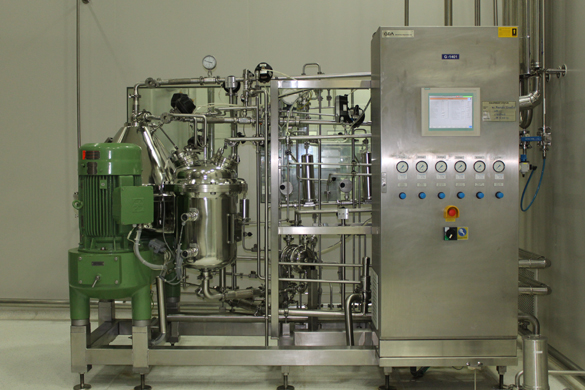

MJ Biotech has a state-of-the-art manufacturing facility located in Maharashtra industrial development corporation (MIDC) biotech park zone, Hingewadi, Pune. The total area of the factory is about 40,000 sq.mts with a built-up area of 15,000 sq.mts. The facility is built according to the standards set by European Medicines Evaluation Agency (EMEA) and US FDA.

The various departments of the plant include product development lab, quality control lab, & warehouses. The manufacturing facility has a microbial suite for recombinant human insulin and analogues, has a fermentation section (inoculum area, fermentation and recovery area) and downstream section (buffer preparation area, initial purification and final purification area). The manufacturing facility is automated and driven by PLC based system. The clean rooms are controlled by a Building management system (BMS).

We have a stringent quality checks and quality control measures in place that ensure our product maintains its standard. Our commitment to uphold quality has earned us the prestigious WHO GMP certification.

Research & Development

Keeping up with our group mission , we wish to reduce costs researching and developing biosimilars that would help in generation high quality pharmaceuticals that are affordable and accessible for the people across the globe.

The products that are currently in development are

Glargine – Under development

Aspart – Under development

Lyspro – Under development

Liraglutide – Under development